For Precise and Close Tolerances

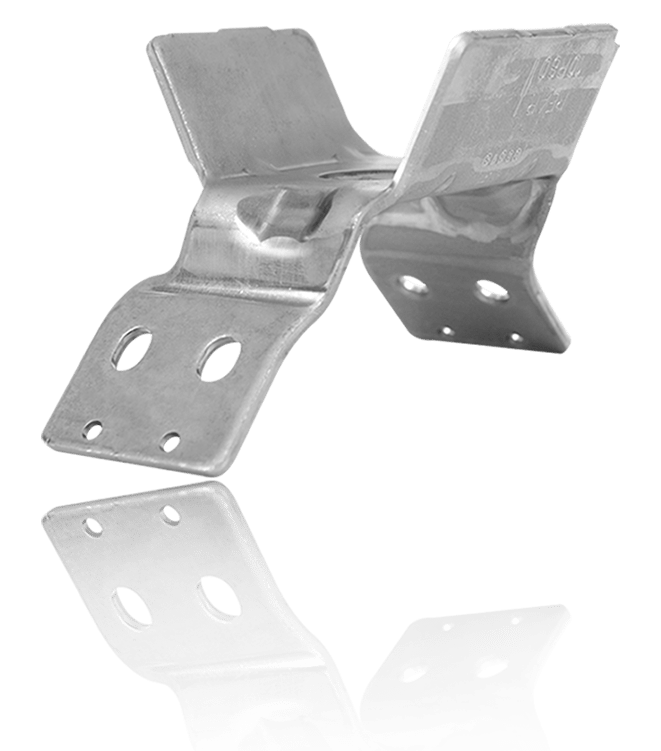

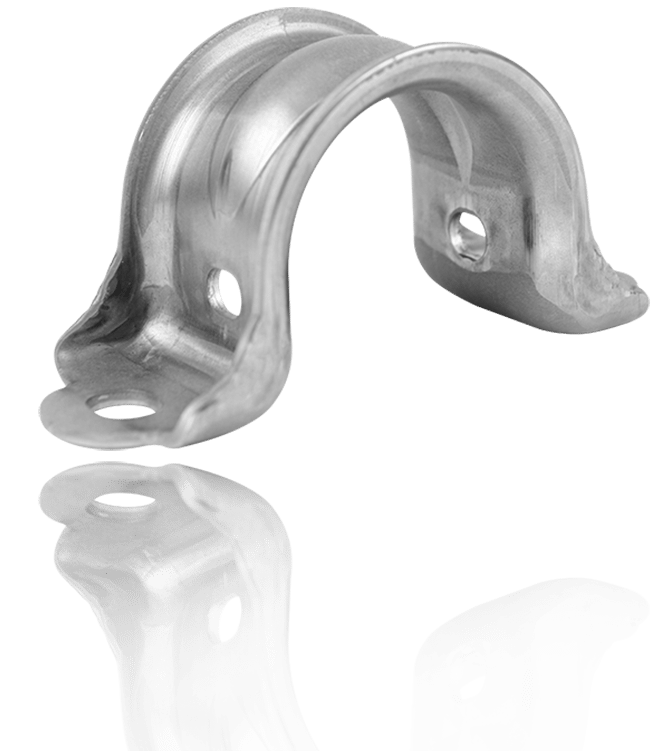

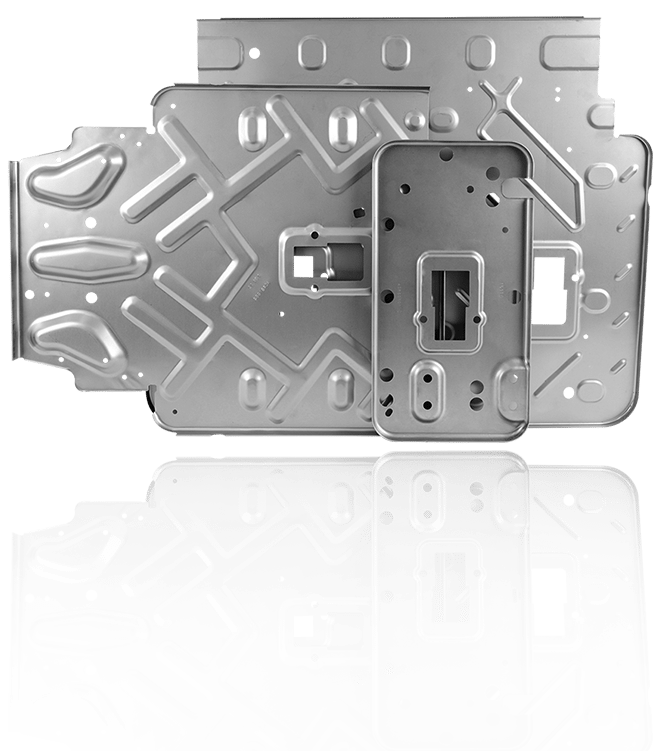

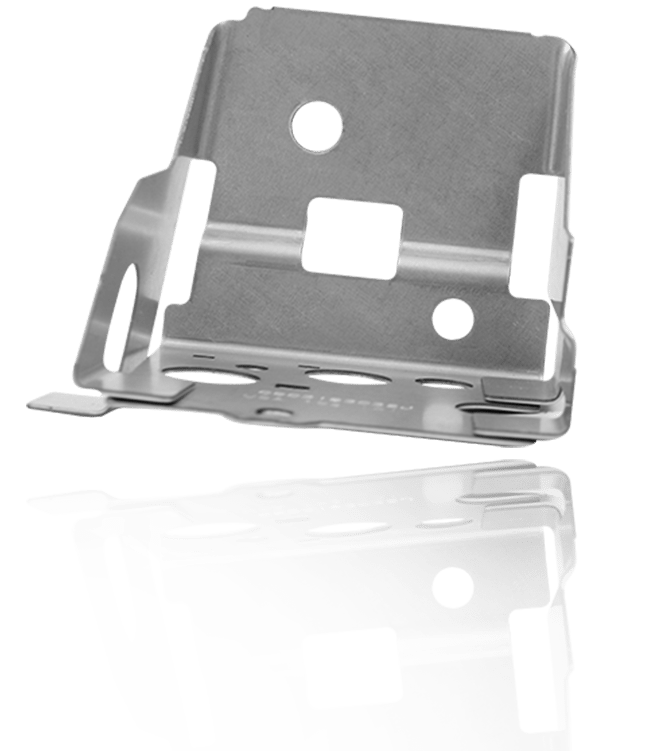

Our state-of-the-art presses have the capacity required for quality, speed, and repeatability. We offer a wide range of services, and our equipment offers advantages for optimum, cost-efficient metal stamping. Our processes and systems ensure we’re producing quality parts each and every time. With progressive and transfer stamping solutions, we offer stamping solutions for a wide variety of parts, sizes, materials, and gauges.

For Quality Parts Produced Quickly

Durable Materials, Stamped Precisely

We start with the best materials

Monitoring starts with the raw material we use to make your parts. Materials we stamp include hot and cold-rolled steel, high strength low alloy, galvanized steel, stainless steel, aluminum, brass, dual phase, pre-painted steel and more. See everything we do on our capabilities table.

Start a Project

Don’t wait for something to go wrong.

Have parts you’re ready to produce? Don’t risk losing time, money and your reputation. You shouldn’t wait for something going wrong in your parts production to consider a better way. Use a team of professionals you know you can rely on for perfection, every time.